Why Purchase a Plastic Bag Making Machine?

Is your business a part of the consumer goods industry? Are you constantly worried about the condition in which your product reaches your end consumer? Are you looking for specialized packaging solutions to avoid mishaps during the distribution process? If your answer for the previous questions was ‘Yes’, then you are in the right place!

Just like you, every businessman who deals in the consumer goods industry knows how difficult it is to ensure product quality throughout the distribution process. Take for instance, the food packaging industries. Food and beverage manufacturers search high and low for packaging options. The reason behind this is two-fold. While the main reason behind the extra focus on appropriate packaging material is to ensure that the product remains well-preserved until it reaches the consumer, such industries also have to meet federal regulations, especially in case of perishable goods. And failure to meet such guidelines result in heavy fines and/or duties. This makes it all the more crucial to pick the most appropriate packaging options. This brings us back to the point about specialized packaging options.

Why Plastic Packaging?

While there are multiple alternatives and materials that can be used to package food, plastic food packaging has always been the most preferred option. Plastic has retained this popularity over the years due to its adaptability and durability. Take a look at some of the other benefits plastic food packaging offers:

- Plastic packaging is extremely light-weight and doesn’t require a lot of storage space either.

- Plastic packaging can survive extreme environments and don’t easily degrade in hot and cold temperatures. The durability that plastic offers ensures product protection during transportation, allowing you to rest easy without worrying about damage or loss of inventory during the distribution process.

- Plastic packaging also allows manufacturers to easily print eye-catching, high-quality custom designs, and thereby increase product visibility in a retail setting.

- Plastic packaging is highly economical in comparison to other packaging options and its low cost makes it most preferred option among various industries.

Impact of Manufacturing Plastic Bags

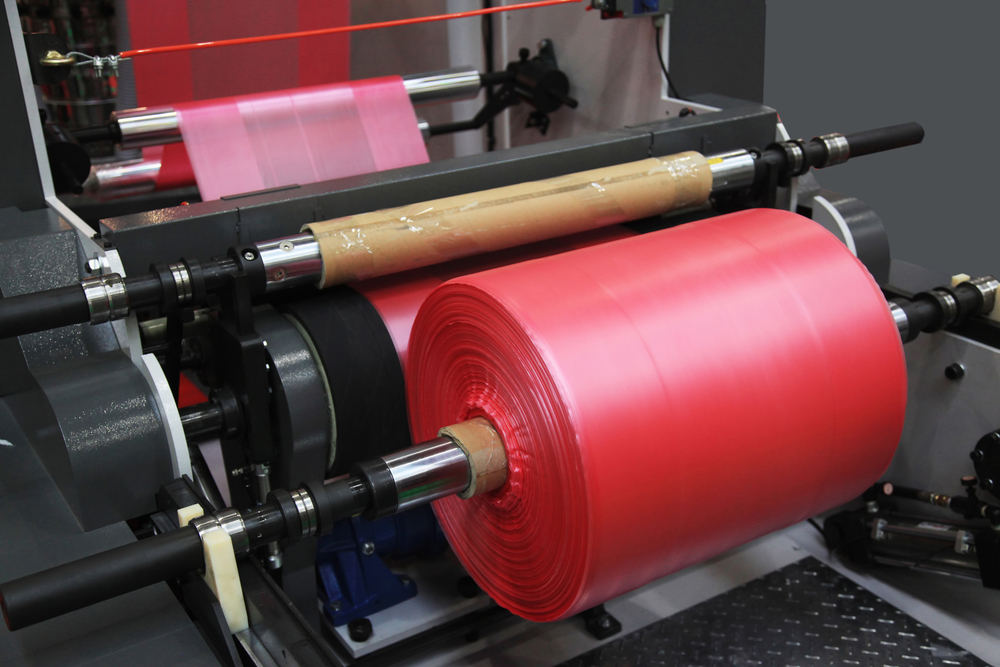

Because of the widespread use of plastic, the production costs associated to plastic packaging is significantly lower as well. According to a study conducted by United States EPA, plastic bags use 40% less energy to produce and generate 80% less solid waste than paper. But, the most surprising revelation from this study was that a pound of plastic takes 91% less energy to recycle as compared to a pound of paper! These numbers can be significantly lowered if you produce your plastic packaging in house. Producing your plastic packaging in house allows you to customize and create packaging depending on your business needs at your convenience! Not only that, but you can also monitor the quality of the raw material as well as the final output and make changes in your process in case of unsatisfactory performance of the plastic packaging all under one roof.

If you need more information on how producing plastic packaging in-house can help your business or are looking to purchase special purpose plastic bag making equipment, contact XL Plastics on +91 265 2830155. Our expert consultants will be happy to assist you with all your queries and help you with all the information you need to make your purchase!