Plastic Bag Making Machine Copy

If you are looking for the best plastic bag manufacturing machine, look no further! We’ve got an array of top performing bag making machines that will meet your requirements. Here are our top performing machines:

Any sorts of bags that are used in many ways can easily be made with these machines. Depending on the type of bag which you require, different types of machines are used.

There are various types of bag making machinery available these days that can make bags out of plastic in a significant way. Our best performing bag making machines are perfectly suited to meet your needs. Some of the best ones are side seal bag, bottom seal bag, t-shirt bag, soft loop handle bag, patch handle bag and zip lock bags. You can choose the one depending on what sorts of bags you want to make.

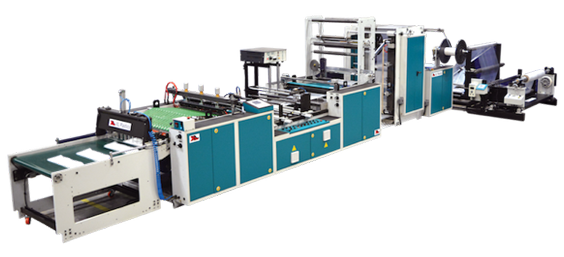

SIDE SEAL BAG

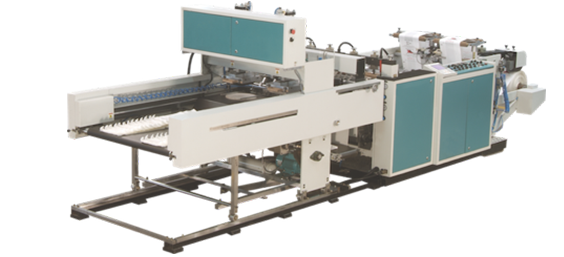

Side Seal Bag making Machine

This bag making machine has its own specialties. The side weld bag making machine can deliver up to 250 strokes per minute which is perfectly suitable for LDPE / HDPE / PP / BOPP films. Using various attachments available for this machine, you can make different sorts of bags just as bottom gusset, inside or outside lip former, handle punch, pre-sealer, lateral sealer, perforation, tape applicator for courier bags and more. Some of the top models available are SS 600 Delta, SS 800 Delta and SS 1000 Delta.

Side Seal Zipper Bag Making Machine

For zip lock bag making machines are concerned, the best model is Zip 400 Delta with speed up to 100 strokes per minute. It has a water cooled pressure plate which creates a strong seal.

Machines that we manufacture are designed especially for constant duty and maintenance free operation. The standard features of the models that we offer make them more efficient, operation friendly and reliable!

Semi-Automatic Soft Loop Handle Bag Making Machine

This machine is used for attaching the Loop Handle to a Side Seal or Bottom Seal bag.

It is capable of giving a production of about 15-20 bags/min depending on the Operator. The machine is operated through a Foot switch which will Open the bag, Insert the Loop Film and seal both the handles in one stroke.

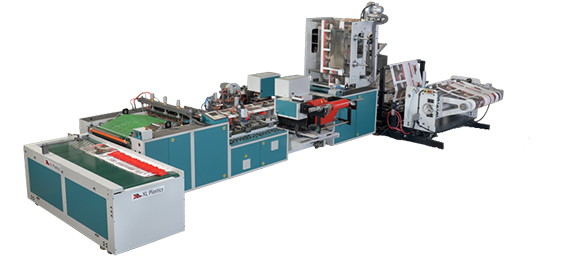

Automatic Soft Loop & Patch Handle Bag Machine

The Automatic machine will convert either a Tubular roll or a Lay flat film into a Side Seal bag and Attach the Loop handle or a Reinforced Patch handle Automatically inline on the machine. The machine is equipped with a Dual Servo System for higher productivity and to maintain tension on the film. The machine is capable of running upto a maximum speed of 100 Strokes/min.

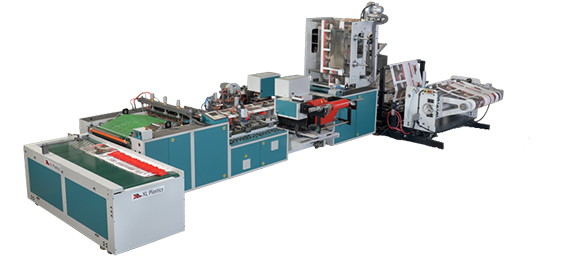

Automatic Soft Loop & Patch Handle Bag Machine

The Automatic machine will convert either a Tubular roll or a Lay flat film into a Side Seal bag and Attach the Loop handle or a Reinforced Patch handle Automatically inline on the machine. The machine is equipped with a Dual Servo System for higher productivity and to maintain tension on the film. The machine is capable of running upto a maximum speed of 100 Strokes/min.

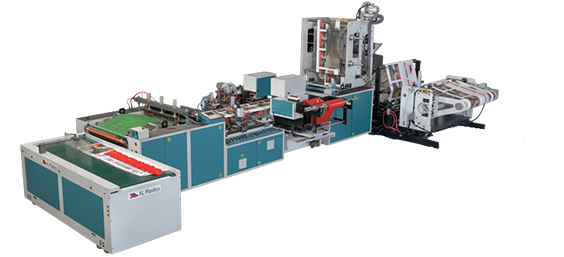

Automatic Patch Handle Bag Making Machine

The Automatic machine will convert either a Tubular roll or a Lay flat film into a Side Seal bag and attach a Reinforced Patch handle Automatically inline on the machine. The machine is equipped with a Dual Servo System for higher productivity and to maintain tension on the film. The machine is capable of running upto a maximum speed of 100 Strokes/min.

BOTTOM SEAL BAG

Bottom Seal Bag Making Machine

When you consider bottom seal bag making machines, we’ve got a huge variety for you to choose from. If you are looking for a High Speed Bottom Seal machine, which is suitable for LDPE, HDPE and PP Film, then go for BS 500 Delta or BS 600 Delta or BS 800 Delta. You can also opt for the most commonly used machine such as DD 800 Delta or DD 250 Delta. They are also a high-speed Servo Driven Double Decker machines which are perfect in terms of efficiency and productivity. You can prefer FLK 1000 Delta or FLK 1500 Delta which are Wide Width Bottom Weld Machine. They are perfect for heavy duty LDPE and HDPE Liner bags.

Flying Knife Bottom Seal Bag Making Machine

Wide Width Bottom Weld Machine specially designed for Heavy duty LDPE and HDPE Liner bags. The technology used here is quite different from the regular smaller width Bottom Seal machine.

Servo Motor Driven machine used for Film Indexing. The sealing of the film is done by a wire seal system which gives a very strong seal. The cutting is done through a mechanically driven Rotary Flying knife. The setting of the cutting knife is much simpler compared to the Shear (scissor type) knife used on regular Bottom seal machine.

T-SHIRT BAG

High Speed T-shirt Bag Making Machine

T-shirt bag makers are available in various models. You can opt for the right one keeping in mind the specific function and as per the width of the bag which you intend to manufacture. You can opt for HSP-VX 450 Delta which is a high-speed bag making machine that can convert up to 200 bags per minute. If you want to get a production rate of 440 bags per minute, then you should opt for the HSP-VTX-350 Delta model which can run at a maximum speed of strokes per minute.

High Speed Twin Track T-shirt Bag Making Machine

The High speed Twin Track T-shirt bag making machine Model VTX-350 Ultima is able to run at a maximum speed of 300 Strokes/minute and thus get a production of 600 Bags/min. You can simultaneously run 2 Printed Pre-Gusseted Tubular Roll on the machine. The machine is equipped with Two Servo Motor & Drive System with Dual Photocell for sensing the Print Mark and thus it is possible to convert 2 Rolls simultaneously

The film is Sealed and Cut using a Hot Knife and stacked together Automatically into bunches of 50 bags. Once the Batch count is reached, the Gripper function on the machine will take the Bunch of bags forward to the Online Punching station where the Handle Punching is done and you get the ready finished bags on the Auto Conveyor.