Plastic Bag Making Machines 101: Types and Uses

Plastic bags or poly bags are an extremely popular choice among lots of retail businesses due to their ease of production and procurement as well as their cost effectiveness. There are multiple types of carrier bags available today and each of them is produced using different types of machines. Take a look at the various plastic bag making machine available:

-

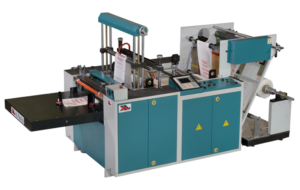

- Bottom Seal Bag Making Machines

Bottom Seal Bag Making Machine

-

- The

bottom seal bag making machine

-

- makes bottom sealed plastic carrier bags using tubular rolls of different sizes. They are used to produce standard bottom seal bags, handle punch bags, multi-hole punch bags, and twin sealed handle punch bags, using the corresponding dies to shape the handles of the bags.

Depending on the length, width and application of the bag, Flying Knife bottom seal bag making machines can also be used.In such machines, the sealing of the film is done by a wire seal system which provides a very strong seal, while the cutting is done through a mechanically driven Rotary Flying knife.

-

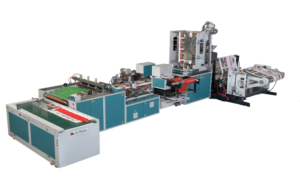

- Side Seal Bag Making Machines

Side Seal Bag Making Machine

-

- As the name suggests, a

-

- is used to create side sealed plastic bags by converting either a Lay flat sheet or a tubular roll of PE or PP material. Depending on the type of handle and use of the plastic bag, you can choose from:

-

-

- Automatic Patch Handle Bag Making Machine

- Automatic Soft Loop Handle Bag Making Machine

- Side Seal Zipper bag making machine

- Automatic Soft Loop & Patch Handle Bag Machine

-

-

-

- Soft Loop & Patch Handle Bag Making Machine Types

Soft Loop Handle Bag Machine

-

- These machines are used for attaching either loop or patch handles to side and bottom sealed plastic carrier bags. In case of loop handles, plastic strips are welded to the inside of the bag, allowing the complete volume of the bag to be utilized.

Whereas, patch handle bag making machines include a glued on patch around the die-cut handle to provide extra strength. Such bags are most commonly used in furniture and clothing stores that retail in bulkier items. There are four variants of such machines, namely:

-

-

-

-

- Semi Automatic Soft Loop Handle Bag Making Machine

- Automatic Patch Handle Bag Making Machine

- Automatic Soft Loop Handle Bag Making Machine

- Automatic Soft Loop & Patch Handle Bag Machine

-

-

-

-

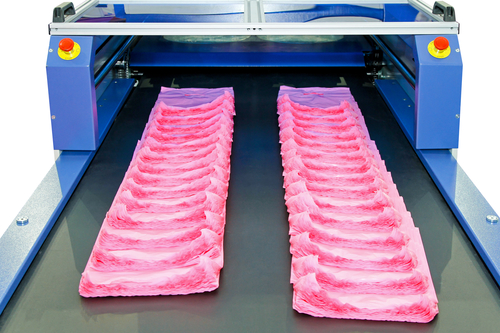

- T-Shirt Bag Making Machine

T-Shirt Bag Making Machine

-

- The

- produces your everyday single use shopping bag or grocery bag using HDPE since they are mass produced at a very low cost. Such machines first cut and seal the plastic film using a hot knife, after which the bags are forwarded to the punching station where he handle punching is done to receive the finished products.

As you can see, depending on the functionality of the bag as well as the intended use, the type of machine used post the extrusion process vastly differs. Therefore, it is important to carefully identify your needs in terms of type and style of the plastic bag as well as the quantity and quality required before deciding to purchase a plastic bag making machine. If you are looking to purchase a plastic bag making machine, get in touch with us at XL Plastics and call us on +91 265 2830155 and let us help you make a well-informed decision.